Armor Shield custom mold for fire customers

Classification:

- Detailed Description

-

- Commodity name: Armor Shield custom mold for fire customers

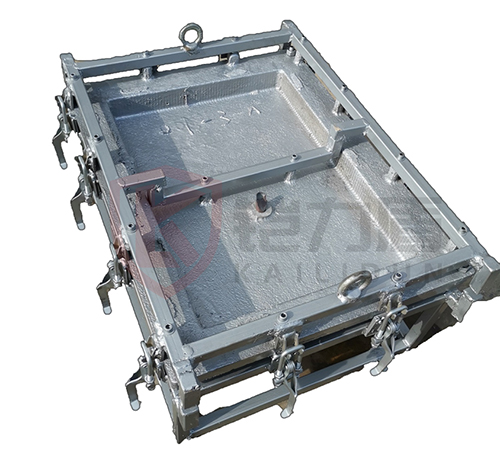

There is no doubt about the advantages of armored shield in mold opening and customization of rotational molding products. Our company has a first-class team of rotational molding engineers and decades of rotational molding industry background. At present, the factory covers an area of 20000 square meters. Our mold processing department has design, casting, processing center and mold back processing, and nearly 10 full-automatic rotational molding machines. In addition to rotomolding boxes, we of course also process other rotomolding products, including mold opening, such as kayaks, motor graders, water horses, car fuel tanks, water pontoons, amusement facilities, etc. Friends are welcome to come to consult and customize. Armor Shield CNC Machining Center Armor shield custom mold has the following three advantages: 1. Low cost: As a military rotomolding box manufacturer, it has a professional rotomolding mold design, customization, and production team. Regardless of time efficiency, product quality, and mold cost, the whole is more cost-effective; 2. Excellent quality: professional forged aluminum and cast aluminum molds, military box products are easy to demould, not easy to damage, no trachoma and pores on the surface, and the products are more delicate; 3. Good service: the whole process of mold design, manufacturing and production is served, and the professional and technical drawings are confirmed. Strong design ability, short mold production time cycle and high efficiency; Manufacturers are more guaranteed after-sales service. Car fuel tank, water horse, washing machine

1. project background

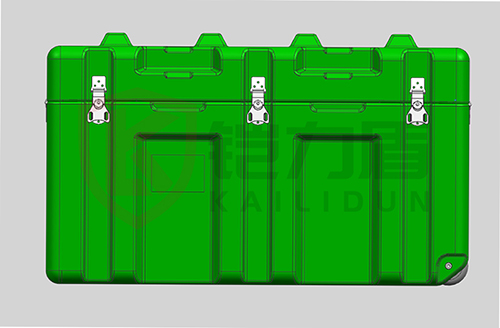

A fire brigade in Sichuan looks for a suitable box type to pack and transport its fire fighting equipment;

However, due to the different sizes of fire fighting equipment, some fire fighting equipment did not find a box type just close to the size. The size of the existing military rotational molding box is too small to fit its fire fighting equipment. The size is too large, which is too wasteful and inconvenient for its transportation;

The customer because Shanghai armored shield plastic technology co., ltd. supports professional customization, hope we can give a suitable customization plan.

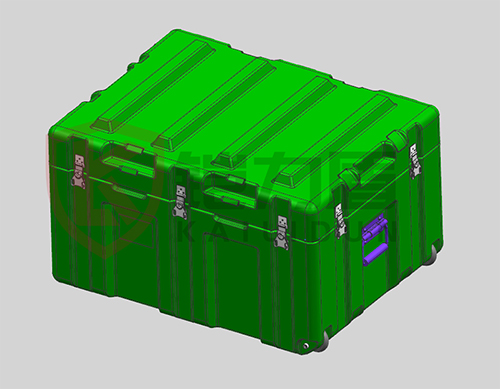

2. Solutions

Based on the fire brigade's demand for a more suitable size of rotomolding military box, the armored shield rotomolding engineer team gave a customized plan: according to the size of the equipment, the rotomolding box that is just close to the size of the equipment is customized, and the EVA sponge lining with appropriate thickness is matched, the overall shock absorption and impact resistance are stronger, and the outer size of the protective box is minimized while providing safer protection for the equipment itself, thus reducing transportation and storage costs, it is also easier to carry and transport;

3. programme process

Provide equipment size → determine the appropriate size in the box → confirm the three-dimensional design drawing scheme of the rotomolding box → confirm the mold drawing → confirm the mold customization production → confirm the test mold sample → mass production

4. Program Advantages

Low cost: as a manufacturer of military rotomolding boxes, Shanghai armored shield plastic technology co., ltd. has its own rotomolding mold design, customization and production team, which is more cost-effective in terms of time efficiency, product quality and mold cost.

Excellent quality: professional cast aluminum mold, military box products are easy to demould, not easy to damage, no trachoma and pores on the surface, and the products are more delicate.

Good service: mold design, manufacturing, production process service, professional and technical docking drawings confirmation; Strong design ability, short mold production time cycle and high efficiency; Manufacturers are more secure after-sales.

[armored shield testing certification]]:IP66 international waterproof and dustproof standard 75 ℃ High Temperature Test GJB 150.3A-2009 -55 ℃ low temperature test GJB 150.4A-2009 Salt spray test GJB 150.11A-2009 Drop test GJB 2711-1996 Inclined impact test GJB 2711-1996 Random vibration test GJB 150.18A-2009 Pressure test GJB2711-1996

Key words:

rotomolding airdrop box | safety protection box | server rack box | aviation aluminum box | cold chain insulation box | fire cart

Previous:

Online consultation

If you are interested in our products, please leave your email and get the product quotation for free, thank you!